Flat Bars And Bars

Flat bars and bars are made from pure metals or alloys and are available in different types of packaging. These products are mainly used in building, the automotive industry, the electrical and electromechanical industries, electronics and white metal casting.

They can be used alone to fill and/or top up tinning baths. They are also used for traditional brazing. In this case, they are combined with a flux so that the parts can be pickled before soldering. The METACONCEPT Group collects used baths, off- cuts, scraps and white metal oxides. Contact our recycling department to find out more.

|

Item no.

|

Designation

|

Composition

|

Dimensions

|

Density g/cm3

|

Solidus/Liquidus

|

Approximate weight

|

Packaging

|

|---|---|---|---|---|---|---|---|

| FE055013 | Flat bar META 30 |

Sn30 – Pb70

|

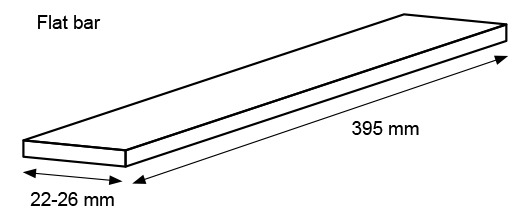

26 x 22 x 9 x 395 mm

|

10,13

|

183°C- 250°C

|

800 g

|

25 kg bundle

|

| FE054993 | Flat bar META 33 |

Sn33 – Pb67

|

26 x 22 x 9 x 395 mm

|

10,01

|

183°C- 243°C

|

800 g

|

25 kg bundle

|

| FE054992 | Flat bar META-ZINC |

Sn – Pb + additifs

|

26 x 22 x 9 x 395 mm

|

10,14

|

181°C – 245°C

|

800 g

|

25 kg bundle

|

| FE055016 | Flat bar META 40 |

Sn60 – Pb40

|

26 x 22 x 9 x 395 mm

|

9,72

|

183°C- 235°C

|

800 g

|

25 kg bundle

|

| FE055015 | META 50 |

Sn50 – Pb50

|

26 x 22 x 9 x 395 mm

|

9,32

|

183°C – 212°C

|

800 g

|

25 kg bundle

|

| FE028929 | Pure lead flat bar |

Pb100

|

26 x 22 x 9 x 395 mm

|

11,35

|

327°C

|

800 g

|

25 kg bundle

|

| FE035273 | Pure tin flat bar* |

Sn100

|

26 x 22 x 9 x 395 mm

|

7,28

|

232°C

|

800 g

|

20 kg bundle

|

| FE051719 | Alloy bar |

Sn – Pb – Bi

|

26 x 22 x 9 x 395 mm

|

10,12

|

183°C – 253°C

|

1 kg

|

25 kg bundle

|

| MF051688 | Bar Sn60 Pb40 |

Sn60 – Pb40

|

380 x 28 x 10 mm

|

8,9

|

183°C- 190°C

|

1 kg

|

20 kg box

|

| FE051726 | Bar SAC305 * |

Sn96,5 – Cu0,5 – Ag3

|

20 x 20 x 295 mm

|

7,32

|

217°C- 219°C

|

1 kg

|

20 kg box

|

| FE051691 | Bar * |

Sn96,5 – Ag3,5

|

20 x 20 x 295 mm

|

7,38

|

221°C- 230°C

|

1 kg

|

20 kg box

|

| FE052236 | Bar * |

Sn99,3 – Cu0,7

|

20 x 20 x 295 mm

|

7,29

|

230°C- 240°C

|

1 kg

|

20 kg box

|

(*) Lead-free alloys – European standard no. 2000 / 53 / CE

Dimensions and weights are always given for informational purposes only and may vary depending on the production run.

Flux pour targettes et barres

|

Item no.

|

Designation

|

Packaging

|

Comments

|

|---|---|---|---|

| DE031855 | Flux PC1 (liquid) – 250 ml | Bottle with applicator brush | Together with META 28,30,33,40,50 and META-ZINC flat bars |

| EO700960 | Flux ZN11 (liquid) – 1 l | Can | Together with META 28,30,33,40,50 and META-ZINC rods |

| CO011269 | Flux Radsol (liquid) – 25 l | Can | Together with ”EN alloy” bar |

| CO010454 | Flux Alpha A83 – 25 l | Can | For electronic and industrial electrical applications |

|

Designation

|

Uses

|

|---|---|

| Sn30 – Sn33 – Sn40 and META-ZINC flat bars | Zinc metal work, coverings, plumbing, tinning baths |

| Pure lead flat bars | Ballasts, munitions |

| Pure tin flat bars | Surface treatments including tinning cookware, brassware. |

| “EN” bars | Dip tinning for baths. This alloy has been developed for high temperature applications such as soldering materials insulated with a polyurethane layer and for which a high temperature is essential for burning off the insulating layer and enabling the tinning process. Very slight oxidation of the bath |

| Sn60 bars | Tinning and industrial, electrical and electromechanical assemblies. |

| SAC305,Sn96,5 – Ag3,5 and Sn99,3 – Cu0,7 bars |

Lead-free alloys specifically for use in tinning baths for copper wires and electronic components. For feeding wave soldering machines For industrial electrical and electromechanical applications. |

The product safety information sheet below is available upon request from the METACONCEPT Group.

Solder bars are generally used to fill baths for assembling parts via dipping or passing them under a wave (performed on the surface of the bath). In all cases, the parts being assembled must be pre-treated (cleaned + fluxed).

The temperature of the bath must be brought to around 20°C above the liquidus temperature.

The T010-type deoxidising powder traps oxides that may be present on the surface of the bath.

Covering the bath with grease also helps to prevent the appearance of oxides.

Flat bars can be used as described above and, more generally, in manual procedures using a propane or oxy-acetylene blow torch or a soldering iron.

The parts must be brought to a temperature of around 15°C to 20°C above liquidus. Melt the filler metal onto the parts being assembled to form a regular bead.

Allow the parts to cool without moving them. When the parts have returned to room temperature, brush the soldering beads using a metallic brush. If necessary, clean the assembly with fresh water or water with a touch of citric or formic acid (1 to 2 %).

To prevent burns caused by the molten metal, it is advisable to wear a protective apron, shoes, gloves, helmet and glasses.

Do not smoke at the workstation.

The workstation must be well ventilated.

Wash your hands when leaving the workstation.

Comments :

Always use a flux suited to the intended use. Contact our technical department to ascertain which product is most suited to your application.

All of the information contained in this document is provided for informational purposes only and the METACONCEPT Group will not be held liable for it.